In the ever-accelerating world of technology, a concept once confined to the realm of science fiction is now fundamentally reshaping industries. It’s a technology so powerful it allows us to hold a living, breathing, and evolving mirror to the physical world. This is the world of the digital twin—a profound leap beyond simple 3D models and basic simulations. It represents a dynamic, virtual replica of a physical object, process, or even an entire ecosystem, continuously updated with real-world data. For businesses, this isn’t just a fascinating technical novelty; it’s a strategic imperative that unlocks unprecedented levels of insight, efficiency, and predictive power.

Imagine a jet engine soaring at 30,000 feet. While the physical engine is experiencing real-time stress, temperature changes, and atmospheric pressure, its exact virtual counterpart—its digital twin—is simultaneously experiencing the same conditions in a secure, cloud-based environment. This virtual engine, fed by a constant stream of data from sensors on the physical object, can be used to predict failures weeks in advance, test software updates without risk, and simulate performance under extreme conditions that would be impossible to replicate in the real world.

This is the paradigm shift that digital twin technology offers. It closes the loop between the physical and digital, creating a symbiotic relationship where one constantly informs and optimizes the other. As we delve deeper, we will explore the intricate mechanics behind this revolutionary technology, its transformative applications across a vast spectrum of industries, the critical components that bring it to life, and the boundless future it promises. This is not just about simulating reality; it’s about understanding, predicting, and perfecting it.

Deconstructing the Concept: What Exactly is a Digital Twin?

To truly grasp its significance, it’s essential to understand what a digital twin is and, just as importantly, what it is not. A digital twin is far more than a static blueprint or a 3D CAD model. It is a robust, complex, and dynamic software representation. The magic lies in the live connection between the physical asset and its virtual counterpart.

At its core, a digital twin is defined by three distinct parts:

A. The Physical Object in Real Space: This is the anchor of the entire system. It can be anything from a single wind turbine or a complex piece of medical equipment to an entire factory floor, a logistics network, or even a sprawling smart city.

B. The Virtual Model in a Digital Space: This is the twin itself. It is a highly detailed and accurate virtual representation of the physical object. It mirrors the object’s geometry, properties, components, and behaviors.

C. The Data Bridge Connecting the Two: This is the lifeblood of the digital twin. A constant, bi-directional flow of data connects the physical and virtual entities. Sensors on the physical object collect real-time data (e.g., temperature, pressure, vibration, location, performance metrics) and feed it to the virtual model. This allows the twin to exist in the exact same state as its physical counterpart. The connection can also flow the other way, with insights from the twin being used to control or modify the physical object.

This continuous data synchronization is what separates a digital twin from a standard simulation. A simulation might model how a car could perform under certain conditions, but a digital twin models how a specific car is performing at this very moment, based on its actual operational data and history.

The Engine Room: How Digital Twin Technology Works

Creating and operating a digital twin is a sophisticated process that integrates several cutting-edge technologies. The workflow can be broken down into a series of interconnected steps that enable this seamless mirroring of reality.

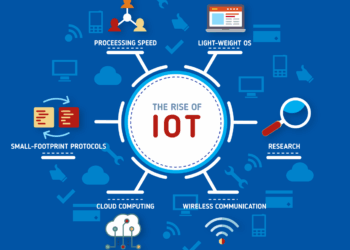

A. Data Acquisition through Sensors: The process begins in the physical world. A dense network of sensors, collectively known as the Internet of Things (IoT), is attached to the physical asset. These sensors are the sensory organs of the twin, constantly gathering data on every imaginable parameter: performance, environmental conditions, operational status, and more.

B. Data Communication and Aggregation: The raw data captured by the IoT sensors is transmitted securely through communication networks (like 5G, Wi-Fi, or satellite) to a central processing platform. This platform, often hosted on the cloud for scalability and accessibility, aggregates and organizes the immense volumes of information streaming in from countless sources.

C. Data Processing and Analysis: This is where raw data is transformed into actionable intelligence. The aggregated data is fed into the virtual model. Advanced analytics, Artificial Intelligence (AI), and Machine Learning (ML) algorithms are then applied. These algorithms analyze the real-time data in the context of the virtual model, identifying patterns, detecting anomalies, and running predictive models. For instance, an AI might detect a subtle vibration pattern that, based on historical data, indicates an impending bearing failure.

D. Visualization and Interaction: The insights and the current state of the virtual model are presented to human operators through sophisticated visualization dashboards. These can range from 3D interactive models to augmented reality (AR) overlays and detailed analytical charts. Engineers, technicians, and managers can interact with the digital twin, run “what-if” scenarios, and test different operational strategies in a completely virtual, risk-free environment.

E. Action and Feedback Loop: The final and most crucial step is closing the loop. The insights gained from the digital twin are used to drive real-world action. This could be scheduling predictive maintenance, optimizing a manufacturing process, rerouting city traffic, or adjusting a power grid’s output. This action, in turn, changes the state of the physical object, which is then captured by the sensors and fed back into the twin, creating a continuous cycle of monitoring, analysis, and optimization.

The Transformative Impact of Digital Twins Across Industries

The true power of digital twin technology is revealed in its diverse and game-changing applications. It is a versatile tool being adopted by nearly every major industry to solve complex challenges and unlock new value.

A. Manufacturing and Industrial IoT: This is where digital twins first gained significant traction. On a smart factory floor, a digital twin can mirror the entire production line. This allows manufacturers to monitor operations in real-time, predict equipment failure before it causes costly downtime (predictive maintenance), improve product quality by simulating changes to the assembly process, and optimize supply chains.

B. Healthcare and Life Sciences: In healthcare, digital twins are paving the way for hyper-personalized medicine. A digital twin of a human heart, created from MRI scans and fed with real-time data from wearables, can help surgeons simulate complex procedures and predict a patient’s response to different treatments. On a larger scale, a digital twin of a hospital can optimize patient flow, manage bed allocation, and track expensive medical equipment.

C. Aerospace and Automotive: From design to decommissioning, digital twins manage the entire lifecycle of complex assets like aircraft and vehicles. Engineers can test thousands of design iterations virtually, drastically reducing the need for expensive physical prototypes. For in-service aircraft, a digital twin tracks the health of every critical component, ensuring maximum safety and optimizing maintenance schedules, a concept known as “through-life engineering.”

D. Energy and Utilities: Power grid operators use digital twins to simulate demand fluctuations, predict the impact of integrating renewable energy sources like wind and solar, and prevent outages by identifying vulnerabilities in the network. For a wind farm, each turbine can have its own digital twin, which optimizes the blade angle in real-time to maximize energy generation based on current wind conditions.

E. Smart Cities and Urban Planning: A digital twin of a city can revolutionize how urban environments are managed. City planners can model traffic flow to reduce congestion, simulate the impact of new construction projects, manage energy consumption across districts, and plan emergency response routes. This data-driven approach leads to more sustainable, efficient, and livable cities for all residents.

Digital Twin vs. Simulation: Clarifying a Key Distinction

While often used interchangeably, the terms “digital twin” and “simulation” describe different concepts. Understanding this difference is key to appreciating the unique value of a twin.

- A Simulation is a model that operates in a virtual environment to study how a system might behave. It is typically used for analysis during the design phase and does not have a real-time data connection to a physical object. It answers “what-if” questions based on theoretical data.

- A Digital Twin is a living model of a specific physical asset that exists in the real world. Its defining feature is the automated, real-time data connection that keeps the virtual and physical models in sync. It answers the question, “what is happening to my asset right now, and what will happen next?” While a digital twin uses simulation to predict future states, its foundation is built on live, real-world data.

Challenges and Considerations on the Path to Implementation

Despite its immense potential, adopting digital twin technology is not a simple plug-and-play endeavor. Organizations must navigate several significant challenges to be successful.

A. Complexity and Integration: Building an accurate digital twin requires integrating data from numerous sources and systems (e.g., IoT platforms, ERP systems, MES). This technical complexity can be daunting. B. High Initial Investment: The cost of sensor deployment, software platforms, data storage, and the skilled personnel required to build and maintain the twin can be substantial. C. Data Security and Privacy: A digital twin aggregates a massive amount of sensitive operational data. Ensuring this data is protected from cyber threats is a paramount concern. D. Data Fidelity and Governance: The adage “garbage in, garbage out” is especially true here. The accuracy of the twin’s insights is entirely dependent on the quality, accuracy, and timeliness of the sensor data feeding it.

The Future is Twinned: A Glimpse of What’s Next

The evolution of digital twins is only just beginning. The future promises even more sophisticated and interconnected applications. We are moving towards the concept of “systems of twins,” where the digital twins of individual components can be connected to create a comprehensive twin of an entire system—like a whole vehicle, an entire power plant, or a complete supply chain. This will enable a holistic level of analysis and optimization previously unimaginable. Furthermore, as the lines between the physical and digital worlds continue to blur with the rise of the metaverse, digital twins will likely serve as the foundational building blocks, creating persistent, realistic, and economically active virtual worlds that mirror our own.

In conclusion, digital twin technology stands as a testament to the power of data and connectivity. It is the ultimate bridge between the real and the virtual, a tool that transforms inert physical assets into intelligent, self-aware entities. By providing a risk-free environment to test, learn, and perfect, digital twins empower organizations to move beyond reactive problem-solving and into the realm of proactive, predictive optimization. The journey to mirror reality is well underway, and the businesses that embrace it will undoubtedly be the architects of the future.