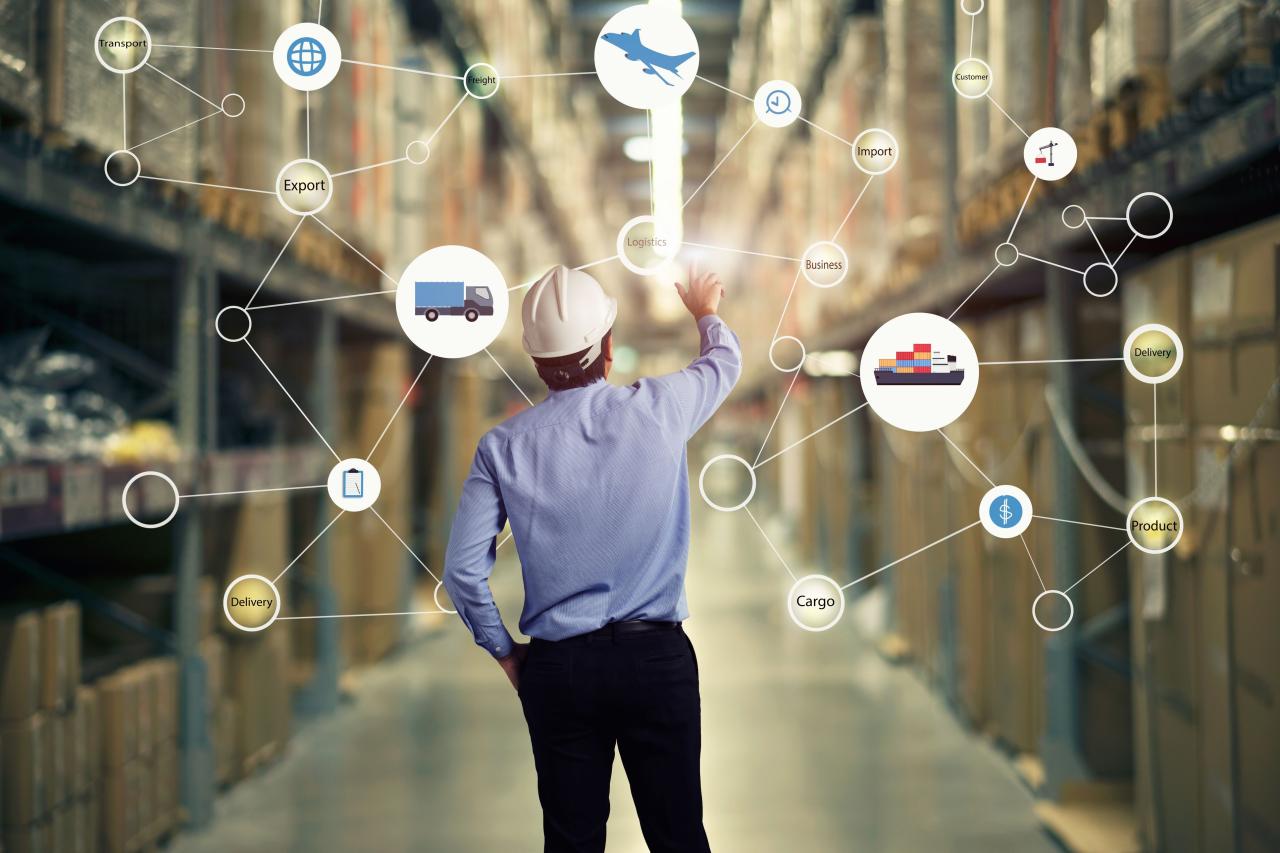

For centuries, the story of logistics was written in diesel, steel, and manual paperwork. It was a world of physical assets—ships, trucks, and warehouses—connected by phone calls, faxes, and ledgers. Today, that story is being rewritten in code, data, and algorithms. The logistics and supply chain industry is in the throes of a profound digital transformation, a paradigm shift so fundamental that it has been dubbed Logistics 4.0. This is not merely about upgrading old systems; it’s a complete reinvention of how goods are stored, handled, and moved, transforming the supply chain from a series of disjointed steps into a single, intelligent, and interconnected ecosystem.

The modern consumer, conditioned by the instant gratification of the digital age, now expects unprecedented speed, transparency, and personalization. This “Amazon effect” has sent shockwaves through the entire supply chain, forcing B2B and B2C logistics operations to innovate or risk becoming obsolete. The pressure is immense: deliver faster, be more flexible, provide real-time visibility, and do it all more efficiently and sustainably than ever before. Meeting these demands is impossible with traditional, analog methods. The only way forward is to embrace a digital-first mindset, leveraging a powerful suite of technologies that are turning data into the industry’s most valuable asset.

This in-depth article explores the multifaceted digital transformation of logistics. We will dissect the key technological pillars that form the bedrock of Logistics 4.0, from the all-seeing eyes of IoT sensors to the predictive brain of Artificial Intelligence. We will examine the real-world applications that are revolutionizing everything from warehouse management to last-mile delivery, and we will outline the tangible benefits that await the organizations bold enough to lead the charge. This is the blueprint for the future of logistics—a future that is smarter, faster, more resilient, and already here.

The Driving Forces: Why Digital Transformation is Non-Negotiable

The shift to a digital logistics framework isn’t happening in a vacuum. It is a direct response to a confluence of powerful global pressures and technological opportunities that have created an urgent need for change. Understanding these drivers is key to appreciating the scale and necessity of the revolution.

A. Radically Evolving Customer Expectations: The modern customer, whether an individual consumer or a large enterprise, demands complete transparency. They want to know exactly where their shipment is, its precise condition, and when it will arrive, all accessible in real-time from their device. This demand for a seamless, Amazon-like experience is the single greatest catalyst for digital adoption.

B. Unprecedented Supply Chain Complexity and Volatility: Recent global events, from pandemics to geopolitical conflicts, have exposed the fragility of traditional supply chains. This has created an urgent need for greater resilience and agility. Businesses can no longer afford to be reactive; they need predictive capabilities to anticipate disruptions and pivot their strategies in real-time to mitigate risks.

C. The Explosion of Data: Every element of the supply chain now generates a torrent of data—from GPS locations and sensor readings to traffic patterns and weather forecasts. In its raw form, this data is noise. However, with the right digital tools, this noise can be transformed into actionable intelligence, enabling optimization and strategic decision-making on a level that was previously unimaginable.

D. The Sustainability Imperative: There is growing pressure from consumers, investors, and regulators for businesses to operate more sustainably. Digital technologies are critical for creating greener logistics operations, enabling everything from route optimization to reduce fuel consumption to smarter inventory management that minimizes waste.

The Technological Pillars of Modern Logistics

Logistics 4.0 is built upon a foundation of interconnected technologies that, when combined, create a system that is far greater than the sum of its parts. Each technology plays a unique and critical role in building the intelligent supply chain of the future.

A. The Internet of Things (IoT): Creating a Hyper-Connected Ecosystem

The Internet of Things is the nervous system of the digital supply chain. It involves embedding sensors, trackers, and other smart devices into nearly every physical asset—vehicles, containers, pallets, and even individual packages. These devices collect and transmit a constant stream of real-time data, providing an unprecedented level of visibility.

- Real-Time Tracking and Tracing: At its most basic, IoT allows companies to know the exact location of any asset at any moment. This eliminates blind spots in transit, improves ETA accuracy, and provides a verifiable chain of custody.

- Condition Monitoring: For sensitive goods like pharmaceuticals, fresh food, or fine chemicals, IoT sensors can monitor critical environmental conditions such as temperature, humidity, vibration, and light exposure. If any parameter deviates from the safe range, an alert is automatically triggered, allowing for intervention before the product is spoiled.

- Predictive Maintenance: Sensors placed on vehicles and warehouse machinery can monitor performance and detect early warning signs of potential failure. This allows companies to shift from a reactive to a predictive maintenance schedule, fixing equipment before it breaks down, which minimizes costly downtime.

B. Artificial Intelligence (AI) and Machine Learning (ML): The Intelligent Core

If IoT is the nervous system, AI and Machine Learning are the brain. These technologies analyze the massive datasets generated by IoT devices and other sources to identify patterns, make predictions, and automate complex decisions.

- Advanced Demand Forecasting: By analyzing historical sales data, market trends, weather patterns, and even social media sentiment, AI algorithms can predict future product demand with a remarkable degree of accuracy, helping companies optimize inventory levels and avoid stockouts or overstock situations.

- Dynamic Route Optimization: AI-powered routing software goes far beyond traditional GPS. It can analyze traffic conditions, weather, delivery windows, vehicle capacity, and fuel costs in real-time to calculate the most efficient route for an entire fleet, saving significant time and money.

- Intelligent Warehouse Automation: In the warehouse, AI-powered vision systems guide autonomous robots for picking and packing orders, while machine learning algorithms optimize the placement of goods to minimize travel time for workers and machines.

C. Big Data and Advanced Analytics: Turning Information into Action

The sheer volume, velocity, and variety of data generated in a modern supply chain is immense. Big Data analytics provides the tools and techniques to process this information and extract valuable, actionable insights that drive strategic improvements.

- Network Optimization: By analyzing data from across the entire supply chain, companies can identify systemic inefficiencies. They might discover that a particular distribution center is a frequent bottleneck or that a specific shipping lane is consistently underperforming, allowing them to make structural changes to their network.

- Performance Benchmarking: Analytics platforms allow managers to track key performance indicators (KPIs) in real-time, such as on-time delivery rates, order accuracy, and cost-per-shipment. This data can be used to benchmark performance against internal goals and industry standards.

- Predictive Risk Management: By analyzing global data streams, analytics can help identify potential disruptions before they impact the supply chain. This could be anything from an impending port strike to a hurricane forming along a key shipping route, giving planners time to activate contingency plans.

D. Blockchain: Forging an Unbreakable Chain of Trust

While often associated with cryptocurrency, blockchain technology offers immense potential for the logistics industry. At its core, a blockchain is a distributed, immutable digital ledger. This creates a single, shared source of truth that is transparent and highly secure, which is perfect for an industry that relies on a complex web of partners.

- Enhanced Transparency and Traceability: Every event in a shipment’s journey—from leaving the factory to final delivery—can be recorded as a transaction on the blockchain. Because the record cannot be altered, it provides an incorruptible audit trail, which is invaluable for high-value goods and for verifying the provenance of products.

- Streamlined Documentation and Payments: The vast amount of paperwork in logistics (bills of lading, customs forms, proof of delivery) can be replaced by smart contracts on a blockchain. These are self-executing contracts where actions, such as releasing payment to a carrier, are automatically triggered once certain conditions, like a confirmed delivery, are met on the blockchain.

E. Robotics and Automation: Revolutionizing Physical Operations

While data and software are the brains, robotics and automation are the muscle of the digital transformation, revolutionizing the physical handling of goods, particularly within the warehouse.

- Autonomous Mobile Robots (AMRs): Unlike traditional automated guided vehicles (AGVs) that follow fixed paths, AMRs use AI and sensors to navigate a warehouse dynamically, working collaboratively with human employees to transport goods for picking and sorting, dramatically increasing efficiency.

- Automated Storage and Retrieval Systems (AS/RS): These are massive robotic systems that can automatically store and retrieve totes or pallets of goods from tall, dense racking structures, maximizing storage space and retrieval speed.

- Drones and Computer Vision: Drones equipped with high-resolution cameras and computer vision software can perform inventory cycle counts in a massive warehouse in a fraction of the time it would take humans, improving accuracy and freeing up staff for more value-added tasks.

The Measurable Rewards of a Digital Logistics Strategy

Embracing Logistics 4.0 is not simply a technological exercise; it is a business strategy that delivers powerful, measurable returns across the entire organization.

A. Radical Visibility and Control: Companies gain a complete, real-time view of their entire supply chain, allowing for proactive management rather than reactive problem-solving.

B. Significant Efficiency Gains and Cost Reduction: Route optimization reduces fuel costs, predictive maintenance minimizes downtime, and warehouse automation increases throughput, all of which contribute directly to the bottom line.

C. A Superior and Differentiated Customer Experience: Providing customers with accurate ETAs, real-time tracking, and reliable deliveries becomes a powerful competitive differentiator that builds loyalty.

D. Enhanced Agility and Resilience: A data-driven supply chain can sense disruptions faster and pivot more quickly, making the business more resilient to the volatility of the modern world.

E. Informed, Data-Driven Decision-Making: Strategic decisions, from network design to inventory planning, can be based on robust data and predictive models rather than on historical averages or guesswork.

In conclusion, the digital transformation of logistics is the most significant evolution in the history of the industry. It is a comprehensive overhaul that touches every link in the supply chain. The technologies of Logistics 4.0 are no longer futuristic concepts; they are practical, accessible tools that are being deployed today to build supply chains that are more transparent, intelligent, efficient, and resilient. For businesses that move goods, the question is no longer if they should embrace this transformation, but how quickly they can lead it.